Le système de découpe de tuyaux dédié Pipe Cut SL offre un traitement précis pour les petits diamètres allant jusqu’à 12″, combinant un pont rigide et un positionnement précis entraîné par mandrin. Il prend en charge une vaste gamme d’applications, incluant la préparation de soudure, les coupes en biseau et les selles. Dotée d’une ouverture/fermeture manuelle du mandrin et d’un ajustement manuel de la hauteur, cette configuration compacte assure des performances fiables et efficaces pour les travaux légers à intermédiaires.

JUSQU'À 12"

DIAMÈTRE DE TUYAUX

JUSQU'À 42'

LONGUEURS DE TRAITEMENT

XPR170

PLASMA D'HYPERTHERM

SUR PLACE

INSTALLATION ET FORMATION

CARACTÉRISTIQUES PRINCIPALES

SYSTÈME PONT ET RAILS

La conception pont et rails offre une stabilité et mouvement exceptionnels et une précision durable grâce à sa conception rigide qui réduit les vibrations. Le contrôleur de hauteur automatique assure un positionnement constant de la torche pour différents diamètres de tuyaux.

SYSTÈME BREVETÉ DE RAILS INVERSÉS

Les rails inversés brevetés du Pipe Cut offrent une protection supérieure contre la poussière et les débris, garantissant un mouvement fluide, une durabilité accrue et une précision à long terme dans les environnements de découpe industrielle exigeants.

SYSTÈME DE ROULEAUX À DEUX ÉTAPES

Le système de support à rouleaux à deux étapes comprend des rouleaux de levage automatiques pour un chargement manuel sans effort. Une fois le tuyau en place, les rouleaux s’abaissent et les roues rotatives prennent le relais, assurant une rotation fluide et contrôlée durant toute la découpe.

SYSTÈME ENTRAÎNÉ PAR MANDRIN

Le système entraîné par mandrin offre une rotation stable et précise pour une coupe constante en toute situation. Il comporte un ajustement manuel de la hauteur et un serrage manuel pour un contrôle simple et fiable, assurant un positionnement exact du tuyau pour différents diamètres.

CHARGEMENT MANUEL SUR ROULEAUX

Le Pipe Cut SL permet aux opérateurs de charger les tuyaux directement par l’avant sur des rouleaux intégrés, qui se soulèvent automatiquement afin d’assurer une manipulation fluide, rapide et fiable des tuyaux.

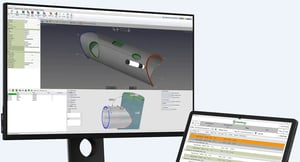

CONTRÔLEUR CNC NX4 DE MACHITECH

Le contrôleur CNC Machitech NX4 offre une interface tactile intuitive, des diagnostics avancés, des flux de travail personnalisables, des analyses 4.0 et un suivi en temps réel, assurant un fonctionnement 24/7, une mise en route plus rapide et une productivité maximale.

LOGICIEL DE DÉCOUPE DE TUYAUX PYPESERVER™

PypeServer est le logiciel de découpe de tuyaux le plus avancé de l’industrie, offrant des intégrations puissantes avec Tekla, Trimble, Acorn, Revit et d’autres logiciels CAO. Il propose un imbriquage automatisé, une connectivité CNC en temps réel, des rapports personnalisables sécurisés dans le nuage et une précision inégalée.

Afficher plus

- Diamètre de tuyau rond - 1,6 po jusqu’à 12 po

- Longueur d’alimentation - 21 pi ou 42 pi, personnalisable

- Entraînement par mandrin - Précis, sans glissement

- Mandrin manuel - Hauteur et serrage du mandrin ajustables

- Rails inversés brevetés - Protection contre la poussière, les débris et les impacts

- Rouleaux d’alimentation - Manuels, sur toute la longueur

- Plasma Hypertherm - Powermax45 à 125, XPR170

- Détachement magnétique de la torche - Se désengage lors des impacts sur la torche

- Hauteur de torche automatique - Maintient une longueur d’arc optimale durant la découpe

- Contrôleur Machitech NX4 - Interface tactile intuitive

- Hypertherm Rotary Tube Pro - Logiciel de découpe de tuyaux, Pypeserver Aussi Disponible

INCLUS AVEC CETTE MACHINE

SUR PLACE PAR NOS SPÉCIALISTES

INSTALLATION ET FORMATION

POUR LA VIE DE LA MACHINE

SUPPORT À DISTANCE ILLIMITÉ

TOUJOURS DISPONIBLE

MEILLEUR SUPPORT AU QUÉBEC

SPÉCIFICATIONS TECHNIQUES

MODÈLES

PIPE CUT SL

DONNÉES D'OPÉRATION

Diamètre min.

1.6"

Diamètre max.

12"

Plasma d'Hypertherm

Powermax45XP à 125, XPR170

Zone de découpe

21' ou 42'

Rouleaux de support

Every 18"

Vitesse découpe max.

500 ipm (12700 mm/min)

Précision du positionnement

0.002" (0.05 mm)

Répétabilité

0.001" (0.03 mm)

Poids de la pièce

25 lbs/pied

CARACTÉRISTIQUES ET OPTIONS

Installation et formation

Inclus, sur place

Support à distance

Inclus, illimité

Extraction des fumées

Multi-zones + mandrin

Dépoussiéreur non inclus, offert en option

Tête chanfrein manuel

Inclus

Tête chanfrein 5-axes

Option

Afficher plus

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

.webp)