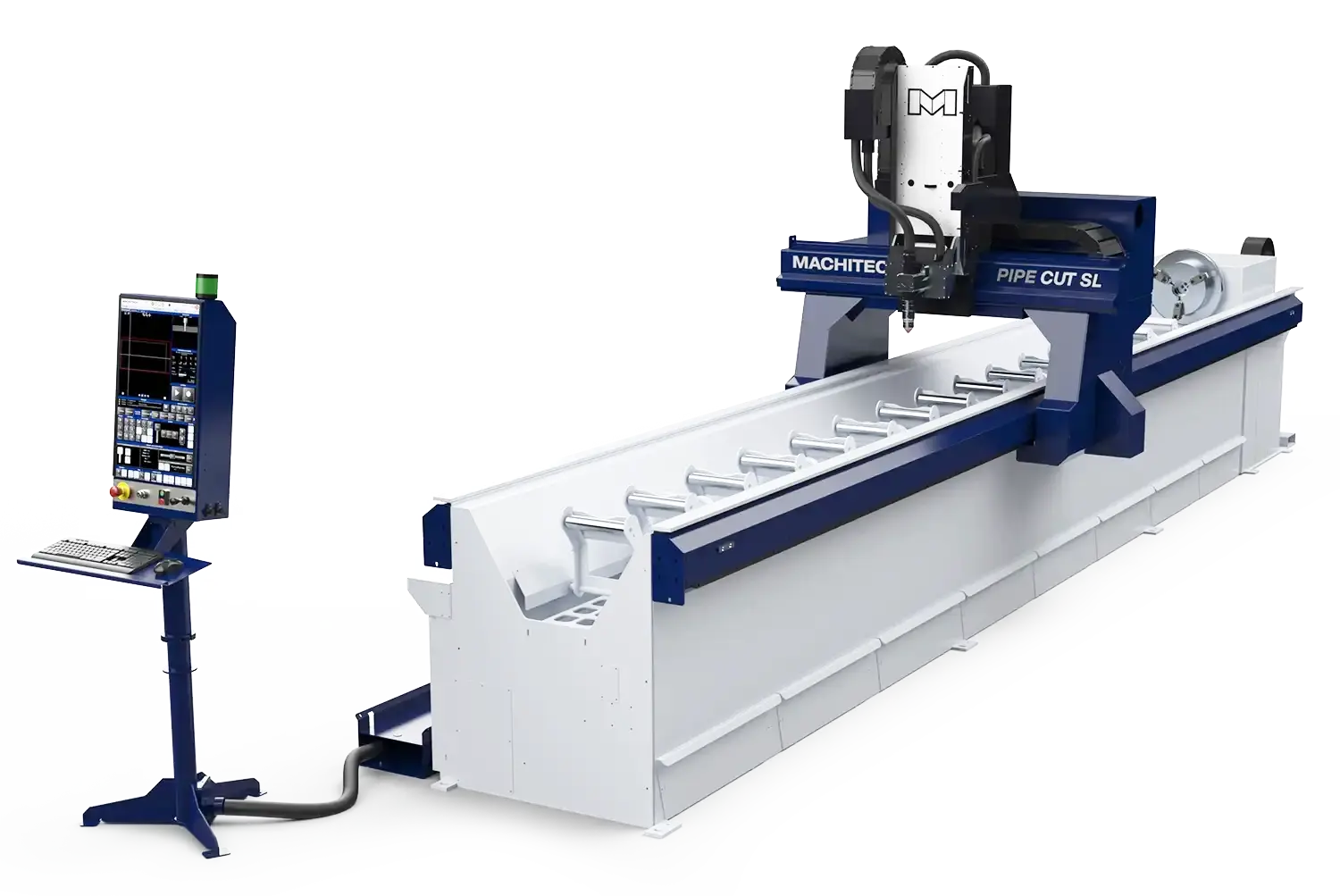

THE PIPE CUT SL

PIPE CUTTING MACHINE FOR SMALL DIAMETERS

The Machitech Pipe Cut SL standalone pipe cutting system delivers precise processing for smaller pipe diameters up to 12″, combining a rigid gantry structure with accurate chuck-driven positioning. It supports a wide range of cutting applications including weld prep, miters, and saddles. Featuring manual chuck open/close and manual height adjustment, this compact configuration provides reliable, efficient performance for light to mid-range pipe fabrication needs.

UP TO 12"

PIPE DIAMETER

UP TO 42'

PROCESSING LENGTHS

XPR170

PLASMA BY HYPERTHERM

ON-SITE

INSTALLATION AND TRAINING

CORE FEATURES

GANTRY AND RAILS SYSTEM

The gantry and rail system delivers exceptional stability, smooth motion, and long-term accuracy thanks to its rigid design that minimizes vibration. The automatic height controller provides consistent torch positioning across varying pipe diameters.

PATENTED INVERTED RAILS SYSTEM

The inverted rails system offer superior protection from dust and debris, ensuring smooth motion, enhanced durability, and long-term accuracy in demanding industrial cutting environments.

DUAL STAGE ROLLER SYSTEM

The dual stage roller support system features automatic lifting rollers for effortless manual loading. Once positioned, the rollers lower and rotating wheels engage, ensuring smooth, controlled pipe rotation throughout the cutting process.

CHUCK DRIVEN FOR PRECISE ROTATION

The chuck driven system provides stable, precise rotation for consistent cutting under all situations. It features manual height adjustment and manual clamping for easy and reliable control, ensuring accurate pipe positioning across varying diameters.

MANUAL LOADING ON ROLLERS

The Pipe Cut SL enables operators to load pipes directly from the front onto integrated rollers, which automatically lift to ensure smooth, fast, and reliable pipe handling.

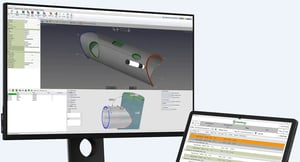

Machitech NX4 CNC Controller

The Machitech NX4 CNC controller offers intuitive touchscreen interface, advanced diagnostics, customizable workflows, 4.0 analytics and real-time monitoring, ensuring seamless operation, faster setup, and maximized productivity.

PYPESERVER™ PIPE CUTTING SOFTWARE

PypeServer is the industry’s premier pipe cutting software, offering robust integrations with Tekla, Trimble, Acorn, Revit and other CAD software. It features automated nesting, real-time CNC connectivity, secure cloud-enabled customizable reporting, and unparalleled precision.

Show more

- Round Pipe Diameter - 1.6" up to 12"

- Infeed Length - 21' or 42' Length, Customizable

- Chuck Driven - Precise, no Slippage

- Manual Chuck - Chuck Height and Clamping

- Patented Inverted Rails - Protects Against Dust, Debris and Impacts

- Feeding Rollers - Manual, on the Entire Length

- Hypertherm Plasma - Powermax45 SYNC to 125, XPR170

- Magnetic Torch Breakaway - Disengages on Torch Impacts

- Automatic Torch Height - Maintains Optimal Arc Length While Cutting

- Machitech NX4 Controller - Intuitive Touchscreen Interface

- PypeServer Software - Industry Leading Pipe Cutting Software

INCLUDED WITH THIS MACHINE

ON-SITE BY SPECIALISTS

INSTALLATION AND TRAINING

FOR THE LIFE OF THE MACHINE

UNLIMITED REMOTE SUPPORT

AVAILABLE WHEN YOU NEED

LARGEST SUPPORT NETWORK

MACHINE SPECIFICATIONS

MODELS

PIPE CUT SL

OPERATIONAL DATA

Minimum Diameter

1.6"

Maximum Diameter

12"

Hypertherm Plasma

Powermax45XP to 125, XPR170

Cutting Zone Length

21' or 42'

Support Rollers

Every 18"

Max. Cutting Speed

500 ipm (12700 mm/min)

Positional Accuracy

0.002" (0.05 mm)

Repeatability

0.001" (0.03 mm)

Workpiece Weight

25 lbs/ft

FEATURES AND OPTIONS

Install / Training

Included, On-Site

Remote Support

Included, Unlimited

Fume Extraction

Zone Downdraft + Chuck

Dust Collector not included, optional

Manual Bevel Head

Included

5-Axis Bevel Head

Optional

Show more

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

REQUEST A QUOTE

Ready to receive a quote for your project? Fill the form below or contact one of our specialists at 888-988-7220.