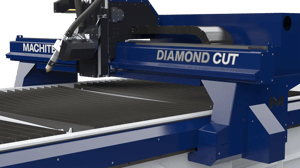

DIAMOND CUT

HD PLASMA TABLE FOR SPEED AND PRECISION.

The Diamond Cut is a compact, high-precision CNC plasma table with a unitized frame and inverted linear rails. Available in sizes up to 12' x 45', it offers reliable performance, Bosch servo motors, and advanced torch controls, perfect for shops needing accuracy and durability in a smaller footprint.

UP TO 12'x45'

TABLE SIZES

XPR SERIES

PLASMA BY HYPERTHERM

5-AXIS BEVEL

RECOMMENDED OPTION

ON-SITE

INSTALLATION AND TRAINING

STANDARD FEATURES

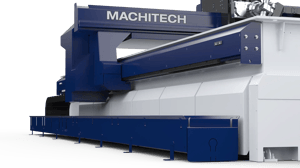

HIGH SPEED MOTION DESIGN

The high speed motion system, powered by dual drive servomotors and the 6"x8" fully welded steel gantry ensure precise, vibration-free cutting with exceptional stability, even at the fastest speed and acceleration of its category¹: up to 3,500IPM and 0.5G.

INVERTED RAILS SYSTEM - PATENTED

The Diamond Cut’s inverted rails offer superior protection from dust and debris, ensuring smooth motion, enhanced durability, and long-term accuracy in demanding industrial cutting environments.

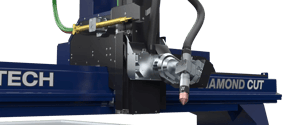

5-AXIS FULL CONTOUR BEVEL HEAD

The 5-axis full contour bevel head option delivers precision and flexibility, enabling complex bevel cuts, A, V, X, K, Y, at angles up to 50° with plasma. Features limitless Rotation for the most complex cuts like countersunk holes.

WATER OR DOWNDRAFT MATERIAL SUPPORT

The Diamond Cut table offers water or downdraft material support, fully welded and built for long lasting industrial use. The downdraft table features drawers for easy part and slag removal, while the water table features removable slag pans and raise/lower water level.

Machitech NX4 CNC Controller

The Machitech NX4 CNC controller offers intuitive touchscreen interface, advanced diagnostics, customizable workflows, 4.0 analytics and real-time monitoring, ensuring seamless operation, faster setup, and maximized productivity.

Hypertherm Pronest 2025 CAD SOFTWARE

ProNest 2025 CAD/CAM is the ultimate nesting software solution from Hypertherm. ProNest 2025 supports all cutting processes, True Hole, automation, ERP integration, advanced nesting, management, recovery.

Show more

- Table Sizes - Customizable, 5’ x 10’ up to 12’ x 45’

- 6"x8" Steel Gantry - Fully Welded Steel Gantry, Fully Covered

- Unitized Design - Compact Machine, Simplified Installation

- Patented Inverted Rails - Protects Against Dust, Debris and Impacts

- Ultra precise motion - Linear Rails on All Axis, 25mm Rack and Pinion

- Magnetic Torch Breakaway - Disengages on Torch Impacts

- Hypertherm Plasma - XPR170, XPR300, XPR460, Multiple Torches

- Automatic Torch Height - Maintains Optimal Arc Length While Cutting

- Machitech NX4 Controller - Intuitive Touchscreen Interface

- Heat shield under gantry - Protects Against Heat and Spatter

- Pronest 2025 CAD Software - Includes Hypertherm CAD/CAM

- Full Process Database - Integrated and Tested Parameters/Cut Charts

INCLUDED WITH THIS MACHINE

ON-SITE BY SPECIALISTS

INSTALLATION AND TRAINING

PHONE AND EMAIL

UNLIMITED REMOTE SUPPORT

TEAM OF 50+ TECHNICIANS

LARGEST SUPPORT NETWORK

MACHINE SPECIFICATIONS

TABLE SIZES

5' x 10' - 12' x 45'

OPERATIONAL DATA

Table Type

Water or Downdraft

Hypertherm Plasma

Maxpro200, XPR170, XPR300, XPR460

Max. Plate Thickness

4" (200 mm)

Z-Axis Clearance

8.5" (300 mm)

Max. Cutting Speed

500 ipm (12700 mm/min)

Max. Rapid Traverse

Speed could be reduced according to local safety regulations. 3,500IPM achieved with X-Motion option.

3,500 ipm (88900 mm/min)

Positional Accuracy

0.002" (0.05 mm)

Repeatability

0.001" (0.03 mm)

Workpiece Weight

Weights are given for a 3" steel plate (40KW).

325 lbs/sq. ft.

FEATURES AND OPTIONS

Install / Training

Included, On-Site

Remote Support

Included, Unlimited

Material Support

Downdraft or Water

Shuttle Table

Optional

5-Axis Bevel Head

Optional

Inkjet / Dot Peen

Optional

Oxyfuel Cutting

Optional, Magnetic Change

IHT Oxyfuel Torch

Optional

Pipe Cutting

Optional, 1.6 to 8" ø

Drilling 7.5 / 12HP

Optional, up to 1.5"

Edge Connect CNC

Optional, for Full Suite

X-Motion System

Optional, powered by Nexen

Show more

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

REQUEST A QUOTE

Ready to receive a quote for your project? Fill the form below or contact one of our specialists at 888-988-7220.