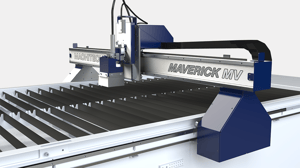

THE MAVERICK MV

COST EFFECTIVE, HIGH PERFORMANCE PLASMA TABLE.

The Maverick MV is Machitech's entry-level CNC plasma table, built for small to mid-sized shops. Durable, low-maintenance, and easy to use, it delivers precise cuts and consistent performance, always ready when you are.

5x5 to 6x12

TABLE SIZES

POWERMAX

HYPERTHERM PLASMA

1.25"

PRODUCTION CUTS

ON-SITE

INSTALLATION AND TRAINING

STANDARD FEATURES

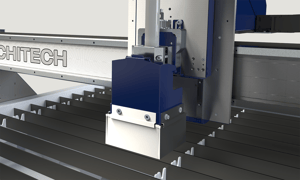

FULLY MACHINED GANTRY

The Maverick MV machine features a 6"x6" precision machined low internia aluminum gantry, allowing for quick, repeatable motion and industrial level performance.

DUAL SIDE - PRECISION DRIVE

Industry leading motion features dual‑side drive with powerful 940 oz‑in Nema 34 motors, advanced zero‑backlash drive system to deliver fast acceleration and highly repeatable positioning.

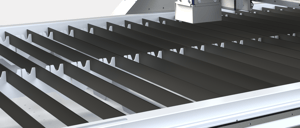

ROBUST TABLE - OFFSET SLATS

Our innovative material support can be used as both downdraft and water table. It features laser cut slat brackets and an offset slat pattern for maximum plate support rigidity. Fork pockets included front and rear for easy placement.

AUTOMATIC TORCH HEIGHT CONTROL

The Maverick’s torch height control maintains optimal arc length, compensating material variations in real-time, ensuring consistent cut quality, reduced consumable wear, and minimal dross formation.

Machitech NX4 CNC Controller

The Machitech NX4 CNC controller offers intuitive touchscreen interface, advanced diagnostics, customizable workflows, 4.0 analytics and real-time monitoring, ensuring seamless operation, faster setup, and maximized productivity.

Hypertherm Pronest LT CAD SOFTWARE

Hypertherm ProNest LT Unlimited CAD/CAM software simplifies nesting workflows, optimizing material usage, automating toolpath generation, and boosting productivity with intuitive controls, advanced simulation, and seamless integration with the machine.

Show more

- Table Sizes - 5'x5', 5'x10' and 6'x12' table sizes

- Fully Machined Gantry - 6"x6" Aluminum Gantry, Low Inertia

- Versatile Table Bed - Can be Used as Both Downdraft and Water

- Offset Slats Support - Laser Cut Slat Brackets with Offset Slats

- Dual V-Rails Motion - Self Cleaning V Groove Bearings on X/Y axis

- Powerful Motors - 940oz Nema 34 Motors, Zero Backlash

- Hypertherm Plasma - Powermax65 to 125 and Maxpro200

- Machitech NX4 Controller - Intuitive Touchscreen Interface, 4.0

- Pronest LT CAD Software - Unlimited Version from Hypertherm

- Laser Positioning System - Allows for Easy Plate Positioning

- Automatic Torch Height - Maintains Optimal Arc Length While Cutting

- Full Process Database - Integrated and Tested Parameters/Cut Charts

INCLUDED WITH THIS MACHINE

ON-SITE BY SPECIALISTS

INSTALLATION AND TRAINING

PHONE AND EMAIL

UNLIMITED REMOTE SUPPORT

TEAM OF 50+ TECHNICIANS

LARGEST SUPPORT NETWORK

MACHINE SPECIFICATIONS

MODELS

5' x 5'

5' x 10'

6' x 12'

OPERATIONAL DATA →

Processing Range

66" x 66" (1676 x 1676 mm)

66" x 126" (1676 x 3200 mm)

78" - 150" (1980- 3810 mm)

Table Type

Water or Downdraft

Water or Downdraft

Water or Downdraft

Plasma Amperage

45 to 125A, 200A

45 to 125A, 200A

45 to 125A, 200A

Max. Plate Thickness

1.5" (38 mm)

1.5" (38 mm)

1.5" (38 mm)

Z-Axis Clearance

5.5" (140 mm)

5.5" (140 mm)

5.5" (140 mm)

Max. Cutting Speed

800 ipm (20320 mm/min)

800 ipm (20320 mm/min)

800 ipm (20320 mm/min)

Max. Rapid Traverse

1200 ipm (30480 mm/min)

1200 ipm (30480 mm/min)

1200 ipm (30480 mm/min)

Positional Accuracy

0.004" (0.1 mm)

0.004" (0.1 mm)

0.004" (0.1 mm)

Repeatability

0.002" (0.05 mm)

0.002" (0.05 mm)

0.002" (0.05 mm)

Workpiece Weight

1530 lbs (694 kg)

3060 lbs (1388 kg)

4410 lbs (2000 kg)

FEATURES AND OPTIONS →

Install / Training

Included, On-Site

Included, On-Site

Included, On-Site

Remote Support

Included, Unlimited

Included, Unlimited

Included, Unlimited

Laser Positioning

Included

Included

Included

Manual Bevel

Optional

Optional

Optional

Pneumatic Scribing

Optional

Optional

Optional

Oxyfuel Cutting

Optional, Choice of fuel

Optional, Choice of fuel

Optional, Choice of fuel

Pipe Cutting

Not Available

Optional, 1.6 to 8" ø

Optional, 1.6 to 8" ø

MACHINE DIMENSIONS →

Nominal Size

5' x 5'

5' x 10'

6' x 12'

Total Width

103" (2616 mm)

103" (2616 mm)

115" (2921 mm)

Total Length

103" (2616 mm)

162" (4114 mm)

187" (4749 mm)

Total Height

53" (1346 mm)

53" (1346 mm)

53" (1346 mm)

Machine Weight

This corresponds to the machine weight with standard equipment. Does not include the plasma source or added options.

1450 lbs (658 kg)

2100 lbs (950 kg)

2500 lbs (1130 kg)

Show more

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

REQUEST A QUOTE

Ready to receive a quote for your project? Fill the form below or contact one of our specialists at 888-988-7220.