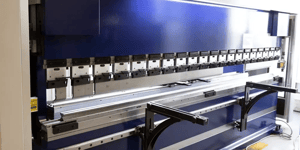

THE H-SERIES PRESS BRAKE

HIGH TONNAGE PRESS BRAKE, USER FRIENDLY OPERATION.

The H-Series combines user-friendly controls, a robust body design, and optimal performance. With versatile tooling capabilities, low operating costs, and advanced safety features, it delivers unmatched bending precision.

40 TO 2,000T

TONNAGE CAPACITY

DELEM 66S

CNC CONTROLLER

CROWNING

CNC, STANDARD

ON-SITE

INSTALLATION AND TRAINING

STANDARD FEATURES

HIGH TONNAGE CAPACITY

The H-Series hydraulic press brakes provide high tonnage for demanding bending tasks. They handle thick materials and large parts with consistent power and precision, ensuring reliable performance and accurate results in every operation.

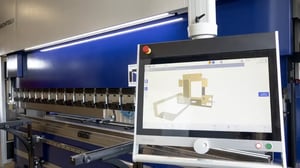

DELEM D66S SMART CONTROLLER

The Delem D66S smart controller features a 2D graphical display, touchscreen interface, CNC control of axes, and intuitive programming. It streamlines setup, ensures bending accuracy, and enhances operator efficiency on every job.

SMART CNC CROWNING SYSTEM

The H-Series uses a smart CNC crowning system to automatically correct deflection. This maintains precise bending angles across the workpiece, eliminates manual shimming, and ensures consistent accuracy in every production cycle.

2 TO 6-AXIS AUTOMATIC BACK GAUGE

The H-Series press brakes feature a CNC-controlled back gauge with 2 to 6 axes. It positions parts accurately, supports complex bending sequences, increases repeatability, and minimizes setup time for efficient production.

MULTI-STEP FINGER DESIGN

The H-Series includes a multi-step finger design on the back gauge, allowing quick positioning for multiple bends without retooling. This improves flexibility, reduces handling, and ensures accuracy during complex bending operations.

LINEAR GUIDED FRONT ARMS

The H-Series press brakes feature linear guided front support arms for smooth, precise movement. They provide stable material support, improve handling of large sheets, and maintain accuracy during bending operations with minimal operator effort.

ADVANCED SAFETY FEATURES

Safety is primordial, and the H-Series was built with industry leading features, including light curtains, safety PLC, and emergency stops. These features protect operators and ensure compliance with the strictest of regulations.

Show more

- High Tonnage Capacity- Hydraulic, 40 to 2,000 tons

- Oil Cooling System - Maintains Consistent Performance

- CNC Crowning System - Automatically Compensates for Deflection

- Linear Guided Front Support Arms - For Large and Heavy Sheets

- Multi-Step Finger Design- Quick positioning for different lengths

- Back Gauge: 2 to 6-Axis - 2-axis (X-R) Standard, 4, 5 and 6 Optional

- Advanced Safety Features - Rear Light Curtain, Laser Front Protection

- Full CSA Certification - Ensures Safety, Compliance and Reliability.

- Wide Tooling Options - European and North American compatibility

- Robotic Tending System - Loads the Press Automatically (Optional)

- Sheet Support Followers - Assists with Larger Sheets (Optional)

- Stroke & Throat Depth - Enables Larger Part Flexibility (Optional)

INCLUDED WITH THIS MACHINE

ON-SITE BY SPECIALISTS

INSTALLATION AND TRAINING

PHONE AND EMAIL

UNLIMITED REMOTE SUPPORT

TEAM OF 50+ TECHNICIANS

LARGEST SUPPORT NETWORK

MACHINE SPECIFICATIONS

HYDRAULIC

H-SERIES

OPERATIONAL DATA

Tonnage

20 to 2,000 Tons

Bending Chart

FEATURES AND OPTIONS

Install / Training

Included, On-Site

Remote Support

Included, Unlimited

Back Gauge

2-axis (X-R) standard, Optional 4, 5 and 6

Multi-Step Fingers

Included

Front Support Arms

Included

CNC Crowning

Included

Safety Features

Included

Robotic Tending System

Optional

Sheet Support Followers

Optional

Production Monitoring

Optional, Real-time

Add. Stroke/Throat Depth

Optional

Automatic Pneumatic Clamping

Optional

Laser Angle Measuring

Optional

3D Profiling capability

Optional, Delem D69S

Show more

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

REQUEST A QUOTE

Ready to receive a quote for your project? Fill the form below or contact one of our specialists at 888-988-7220.