Besoin d’aide pour choisir? Nos spécialistes peuvent vous aider à trouver la machine idéale.

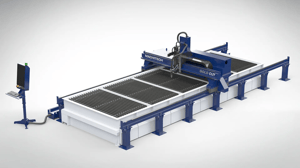

LA GOLD CUT

PONT ET RAILS.

PONT ET RAILS.

CONCEPTION MODULAIRE.

La Gold Cut est un système de découpe au plasma CNC à pont et rails conçu pour offrir une polyvalence et une modularité maximales. Les clients peuvent intégrer leur support de matériel existant, en fabriquer un à partir de nos plans fournis, ou demander à Machitech de fournir une solution complète. Associé à la technologie plasma Hypertherm XPR, le Gold Cut offre un système de découpe industriel abordable et puissant.

JUSQU'À 10x40

GRANDEURS DE TABLES

PLASMA XPR

SOURCES D'HYPERTHERM

AIR OU EAU

OU FABRIQUEZ LE VÔTRE

SUR PLACE

INSTALLATION ET FORMATION

CARACTÉRISTIQUES PRINCIPALES

CONCEPTION PONT ET RAILS

La Gold Cut est conçue pour la polyvalence grâce à sa conception à pont et rails. Elle peut être utilisée avec un bassin existant; un nouveau bassin peut être fabriqué par le client à partir des plans fournis ou encore peut être fourni par Machitech.

CONSTRUCTION ROBUSTE EN ACIER

Le pont en acier entièrement usiné de 6" × 8" offre rigidité et mouvement précis. Combiné à un double entraînement par servomoteurs et à des roulements en V "DualVee" de précision, il assure un fonctionnement fluide, sans vibrations.

RAILS EN V MODULAIRES EXTENSIBLES

Rails sur piédestal au sol, extensibles à l’infini pour soutenir la croissance future. Leur conception à la hauteur des genoux simplifie le chargement, et les chariots surdimensionnés protègent les composantes mobiles, garantissant durabilité, fiabilité et performance constante.

CLASSIQUE OU HAUTE DÉFINITION

Machitech est un partenaire privilégié de Hypertherm et est fier d’offrir, sur la Gold Cut, les plasmas Powermax et XPR de Hypertherm, les chefs de file de l’industrie.

CONTRÔLEUR CNC NX4 DE MACHITECH

Le contrôleur CNC Machitech NX4 offre une interface tactile intuitive, des diagnostics avancés, des flux de travail personnalisables, des analyses 4.0 et un suivi en temps réel, assurant un fonctionnement 24/7, une mise en route plus rapide et une productivité maximale.

LOGICIEL CAD PRONEST 2025 D'HYPERTHERM

ProNest 2025 CAD/CAM est la solution ultime de logiciel d’imbrication développée par Hypertherm. ProNest 2025 prend en charge tous les procédés de coupe, True Hole, l’automatisation, l’intégration ERP, l’imbrication avancée, la gestion et la récupération.

Afficher plus

- Construction modulaire - Réutilisez votre bassin ou fabriquez le.

- Pont en acier de 6" x 8" - Entièrement soudé et protégé.

- Conception pont et rails - Versatilité, installation simplifiée.

- Rails modulaires extensibles - Rails sur piédestal fixés au sol.

- Mouvement ultra précis - Rails en V, roul. linéaires sur le pont.

- Support de torche magnétique – Se désengage en cas d’impact

- Plasma Hypertherm - XPR170, XPR300, XPR460, Powermax

- Contrôle hauteur automatique - Maintien la longueur d’arc optimale

- Contrôleur NX4 Machitech - Écran tactile intuitif, boutons physiques

- Bouclier thermique - Protège contre la chaleur et les projections

- Logiciel CAD Pronest 2025 - Inclus le logiciel CAO/FAO d'Hypertherm

- Base de données complète - Paramètres intégrés au contrôleur

INCLUS AVEC CETTE MACHINE

SUR PLACE PAR NOS SPÉCIALISTES

INSTALLATION ET FORMATION

POUR LA VIE DE LA MACHINE

SUPPORT À DISTANCE ILLIMITÉ

TOUJOURS DISPONIBLE

MEILLEUR SUPPORT AU QUÉBEC

SPÉCIFICATIONS TECHNIQUES

GRANDEURS

5' x 10' - 12' x 45'

DONNÉES D'OPÉRATION

Type de table

Construisez-la, réutilisez la vôtre

Plasma d'Hypertherm

XPR170, XPR300, XPR460, MAXPRO200, Powermax

Épaisseur plaque max.

4" (100 mm)

Espace sous le pont

6.5" (165 mm)

Vitesse de découpe max.

500 ipm (12700 mm/min)

Vitesse traverse max.

La vitesse peut être réduite selon les règlements de sécurité locaux.

1,000 ipm (25400 mm/min)

Précision positionnement

0.003" (0.075 mm)

Répétabilité

0.001" (0.03 mm)

CARACTÉRISTIQUES ET OPTIONS

Installation et formation

Inclus, sur place

Support à distance

Inclus, Illimité

Support matériel

Option, Water or downdraft

Table alternante

Non disponible

Tête chanfrein 5-axes

Non disponible

Marquage percussion ou encre

Option

Découpe oxycoupage

Option, magnétique à changement rapide

Torche d'oxycoupage IHT

Option

Découpe de tuyaux

Option, 1.6 à 8" ø

Perçage

Non disponible

Contrôleur Edge Connect

Option, pour Full Suite

Système X-Motion™

Non disponible

Afficher plus

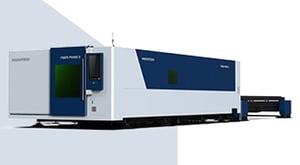

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS