PYPESERVER™ AND MACHITECH:

SMARTER PIPE CUTTING THROUGH SOFTWARE INTEGRATION

January 8th, 2026

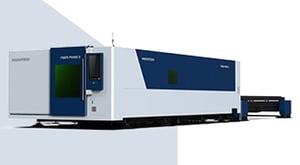

Pipe cutting operations increasingly rely on tight integration between design software and the pipe cutting equipment to improve accuracy and efficiency. Machitech’s next-generation Pipe Cut™ machines are built in North America, feature advanced motion control, and come standard with  PypeServer™ Enterprise software, creating a streamlined workflow from model to machine.

PypeServer™ Enterprise software, creating a streamlined workflow from model to machine.

PypeServer™ is designed to connect directly with common CAD and BIM platforms, allowing pipe parts and assemblies to move from design to fabrication without manual programming. This reduces setup time and limits the risk of errors introduced through file conversions or re-entry of data. It also enables you to print custom labels.

The integration provides several practical advantages on the shop floor. PypeServer™ enables advanced nesting to optimize material usage, supports label printing for part identification and traceability, and allows fabricators to track cut parts throughout the production process. These features are applicable across a wide range of pipe cutting applications, from handrail systems to structural pipe.

By pairing Machitech’s pipe cutting equipment with PypeServer™ software, fabricators can improve workflow consistency and reduce manual intervention. The result is a more connected fabrication process that supports higher throughput, better organization, and improved visibility across projects.

For shops looking to modernize pipe cutting operations, the combination of Machitech Pipe Cut machines and PypeServer™ Enterprise offers a practical, software-driven approach to improving efficiency and control.